It is known that swaying is a big problem for safety and efficiency operation of overhead cranes and gantry cranes. To this end, Weihua develop advanced crane anti-swing control system for the cranes through the establishment of the precise load swing movement mathematical model. This anti-swaying system of cranes controls the traveling speeds of the crane and trolley to eliminate load swing by 95%.

Weihua cranes with electrical anti-swing control system can be widely used in various industrial fields such as machinery manufacturing processing workshops, assembly plants, waste disposal plants, steel mills, power plants, shipyards, construction sites, railways, container terminals, paper industry, metallurgy Industry, etc.

Advantages of Electrical Anti-swing Cranes:

1. Reduce the waiting time of swing, so that the crane's work efficiency increased by 30% or more.

2. Improve the safety of crane operation and reduce the risk of injury to personnel and operating areas.

3. Make cranes into a "crane robot" to achieve automatic control of material handling.

4. Improve the safe operation speed, and further improve the efficiency of the use of the crane.

5. Make the crane easy to operate, reduce the staff training time, and reduce the labor intensity of the operation of employees.

6. Increase the safe working space of the crane.

7. Extend the mechanical life of the crane.

8. Can be adopted by overhead cranes and gantry cranes.

9. Automatically avoid hazards, set up dangerous areas in advance, the control system can automatically avoid it.

10. Vertical system to eliminate deviation, automatically adjust the operating position.

11. Hook pushing function, the crane can automatically run while pushing the hook.

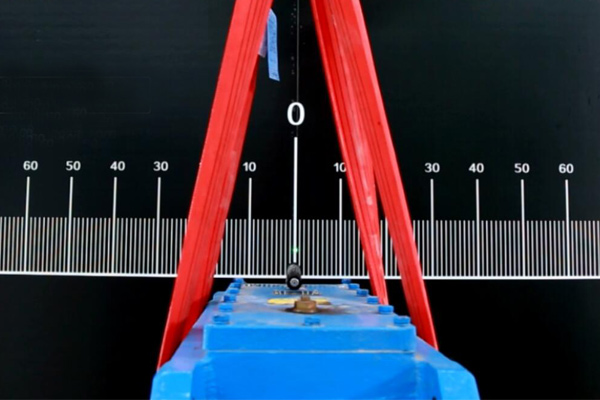

The table below shows the test data of an overhead crane with capacity 32t, lifting height 12m and trolley speed 40m/min.

|

Test Item |

Without Anti-Sway Control |

With Anti-Sway |

|

Swing Amplitude |

20 ~ 100cm or more |

?2cm |

|

Swing Time |

900s |

?2s |

|

Point Positioning Distance |

Hard to control |

Min. 0.5cm |

|

Auto Positioning |

Hard to control |

Repeated positioning accuracy ?0.5cm |

|

Perforation Test Time |

230s |

18s |